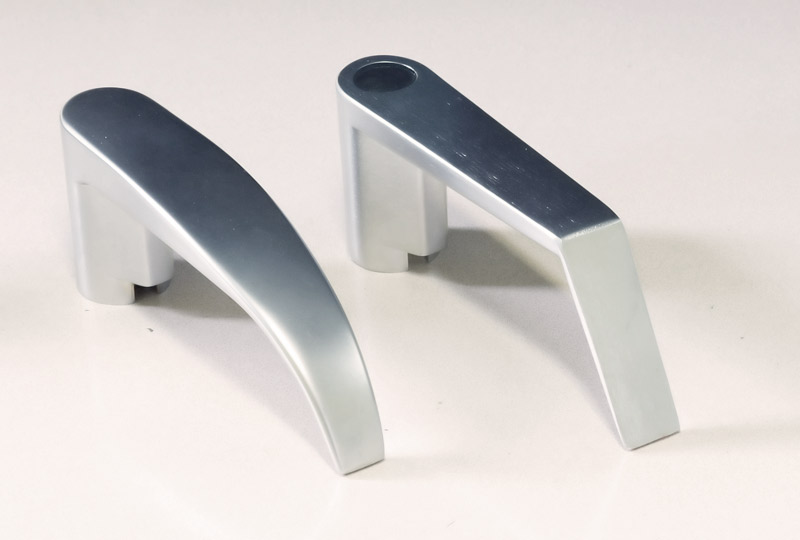

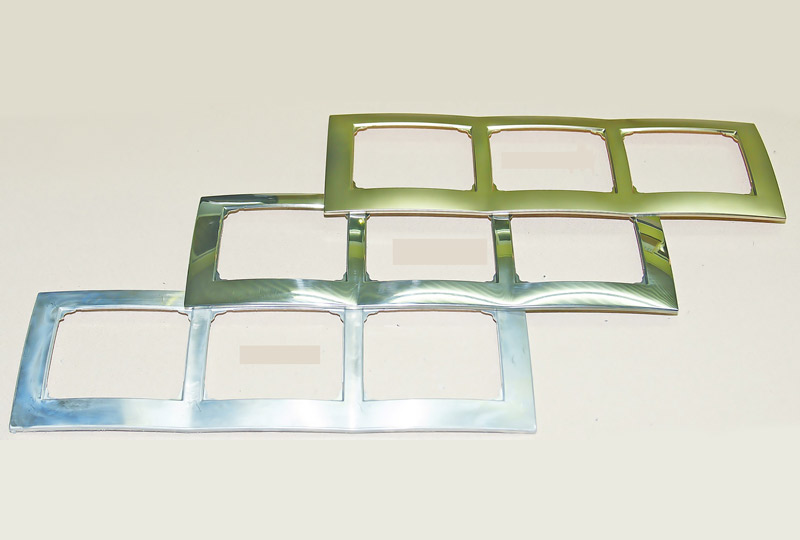

Zamak and Magnesium die casting

Specialist in die casting for galvanic coating finished parts

and technical parts for all sectors

Sectors in which we produce Zamak and Magnesium parts

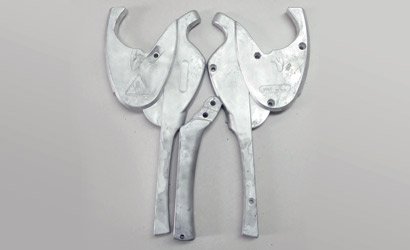

Specialist in die casting for Zamak and Magnesium parts in hot chamber for all sectors.

We have a long experience in the production of parts for superficial treatment, for those parts destined to have very demanding decorative finishes.

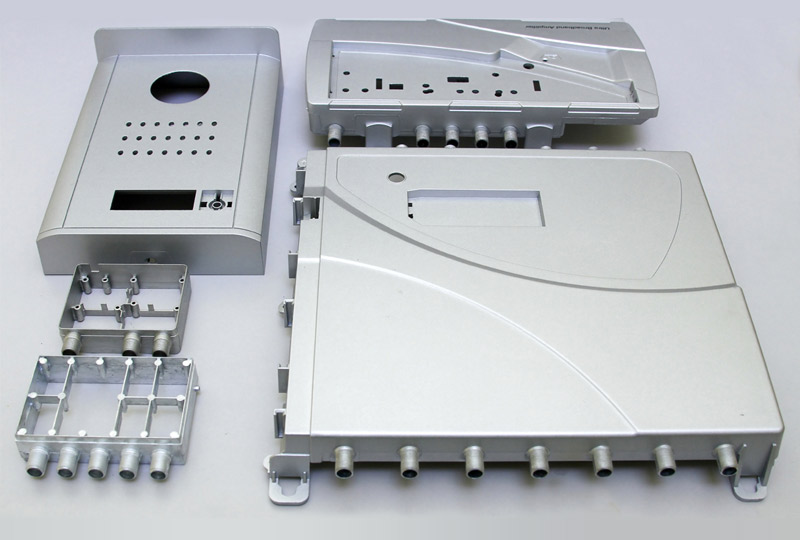

We also have a long experience in the fabrication of technical parts with very thin walls, using the vacuum technology.

We produce pieces in Zamak and Magnesium from different sizes and weights for all the different sectors.

Catalogue: materials and weight

Die casting of Magnesium and Zamak parts in different sizes and weight.

Mould Production

One of the most important differences; between GURELAN and other die casting suppliers is that we have the internal capacity to produce the entire mould including the design, production, assembly and final adjustment.

Also we have a strategic supplier near by at no more than 50 Km, from our facility.

Irrespective of who makes the tool, GURELAN internally; or our supplier, the mold is 100% designed by our development department, which means that the design of the sprues sprue in the injection, the location of the overflow , the position of the inlet channels, etc. are all fully designed internally.

We use the following Software to develop and produce the mould. In accordance with the CAD-CAM philosophy: for the CAD we use Solidworks, Solid Edge and Power SHAPE and for the CAM we use PowerMILL.

Request more information